Products

In recent years, China's conventional plastic extruders and production lines, with excellent cost-effective gradually popular in the international market. At the same time, China has continuously innovating in the field of advanced extrusion technology, and has developed many new extrusion products. Precision extrusion molding can eliminate the follow-up processing methods, better meet the needs of product applications, while reducing material costs and improving product quality. Nowadays, to meet the needs of precision direct extrusion of plastic products, a variety of mature technologies have been pushed to the field, polymer melt gear pump is one of the important means. This technology has been widely used in chemical fiber, film, profiles, pipes, sheets, cables, composite extrusion, granulation and other production lines.

In order to reduce the production cost, it is often necessary to change the color of masterbatch. If it is necessary to change the product, the open processing area will be opened in a few minutes. The split twin-screw extruder can solve this problem. When changing the color, the barrel can be opened quickly and cleaned manually in a few minutes. Thus, the cleaning material can be used less or no, and the cost can be saved.

To improve labor efficiency, in equipment maintenance, the ordinary twin-screw extruder often needs to remove the heating and cooling system first, and then extract the screw as a whole. The split twin-screw is not necessary, as long as a few bolts are loosened, rotating the worm case handle device lifting the upper part of the barrel can open the whole barrel, and then maintenance. This not only shortens the maintenance time, but also reduces the labor intensity.

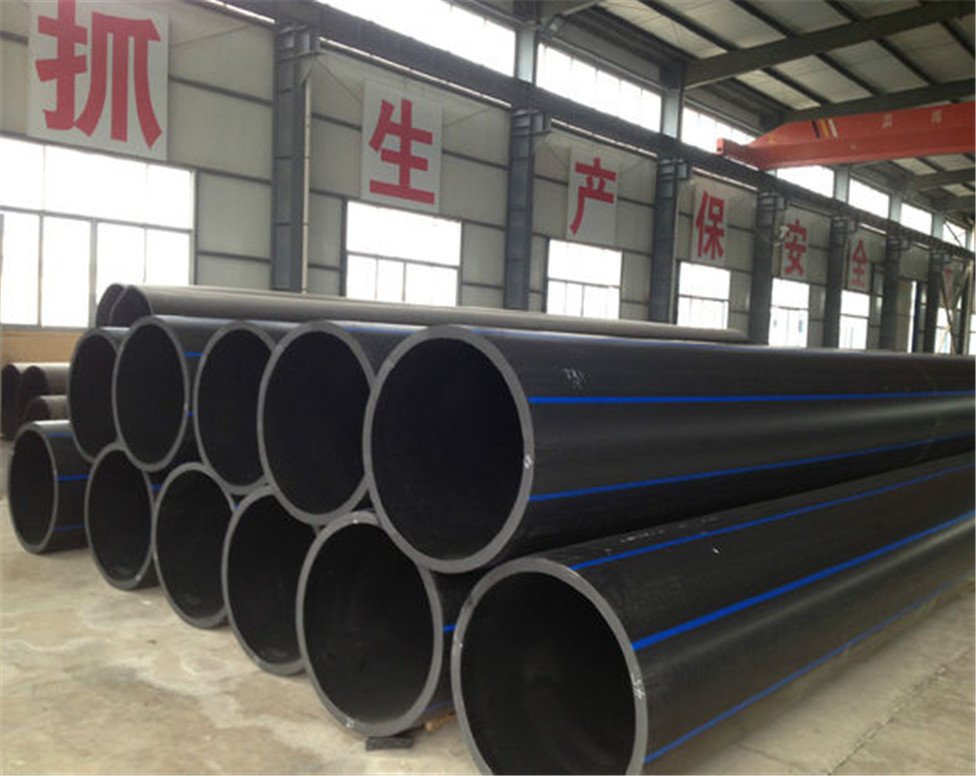

And then understand its special process for plumbing.

In the opposite rotating twin screw feed pipe equipment, the material is acted as a positive displacement transport similar to the gear pump. The reverse twin-screw extruder has low rotational speed, low shearing heat and difficult to decompose materials. Therefore, it does not require high thermal stability of materials, especially suitable for the molding of heat-sensitive materials (such as PVC). Compared with the countercurrent twin-screw extruder, the counter-rotating twin-screw extruder has higher conveying efficiency, better exhaust effect and melting effect. Although the material dispersion and mixing effect is worse than the countercurrent twin-screw extruder, the stable head pressure is stronger, so it is more suitable for direct extrusion products. In addition, the counter-rotating twin-screw extruder can replace the single-screw extruder, which can save the pre-plasticizing and granulating process and directly extrude PVC powder to reduce the cost of products. The counter rotating twin screw extruder is mainly used for extruding PVC pipes. Profiles, plates and prilling. The parallel opposed twin screw extruder has also been applied in large HDHDPE pipe production line.

Anisotropic conical twin-screw PVC extruder is traditionally used for extrusion of PVC products, but in recent years there have been some examples of the application of heterotropic conical twin-screw extruder in the extrusion of polyolefin pipes. Practice shows that it has been basically successful. The aim of this approach is to save energy. A 65-body 132 umm conical twin-screw extruder has a driving motor power of only 37 kW. When extruding polyethylene pipes, the pipe specifications and output can be equivalent to a 75 mm or even 80 mm single-screw extruder, while a 75 mm or 80 mm single-screw extruder has a driving power of at least 90 kW. Foreign countries have already had mature experience in extruding products with parallel counter-rotating twin-screw extruders. In fact, the domestic counter-rotating conical twin-screw extruders with different diameters are still for the consideration of equipment cost. The manufacturing cost of parallel counter-rotating twin-screw extruders is higher than that of counter-rotating conical twin-screw extruders.

In the plastic product processing industry of plastic extruder, the water supply pipe equipment is a kind of teaching production mode with the largest output (about 1/3 of the plastic product output), lower production cost and easier to master production operation. Plastic products extruded by extruders, such as plastic films, pipes, plates, sheets, profiles, wires, cables, packaging bags, rods, nets, composite films, etc., have been widely used in national defense industry, transportation industry, mechanical and electrical products, building materials, agriculture, science, education, health and daily necessities, and have become daily life of people. And an indispensable part of national economic development.

Top